Submersible pumps are essential equipment in various industries. These pumps transport liquids, such as water, oil, and chemicals, from one place to another. Submersible pump spares make up the pump and enhance its functionality, efficiency, and longevity. These spares come in different varieties, serving different purposes and industries. Understanding submersible pump spares is critical for efficient pump maintenance and replacement. This blog post dive into submersible pump spares, exploring their properties, uses, and composition.

Definition and Types of Submersible Pumps Spares

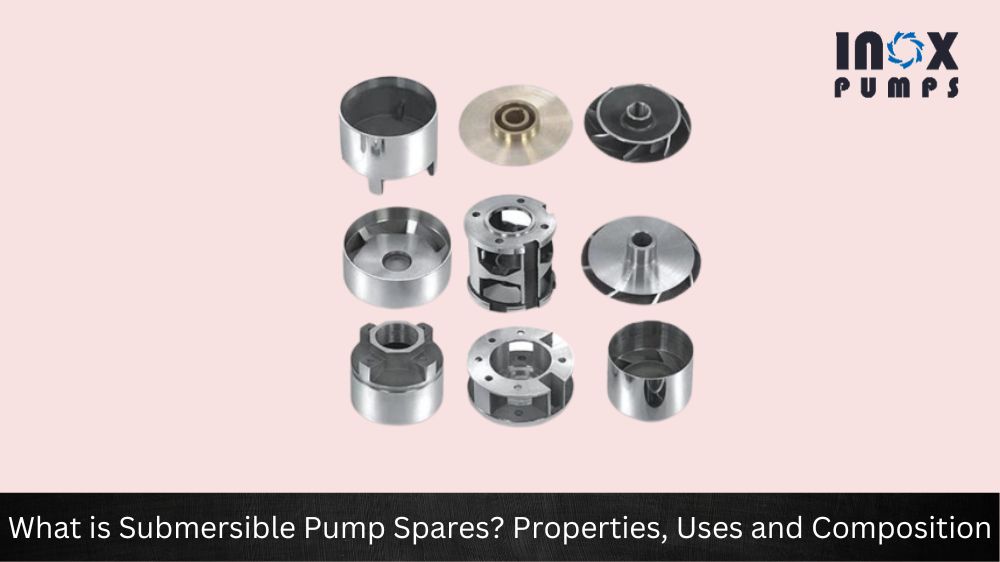

Submersible pump spares are components or parts of the pump that help to enhance the pump’s functionality and lifespan. These spares include impellers, motor covers, control boxes, oil chambers, shafts, couplings, and seals. Each submersible pump spare serves a different function and has a unique composition.

Properties of Submersible Pump Spares

Physical Properties of Submersible Pump Spares

- Submersible pump spare parts are made from cast iron, brass, and stainless steel.

- These materials are selected because they can withstand the high pressures found underwater and offer resistance to corrosion caused by the water.

- The components must be able to support dynamic loading due to changing pressure levels over time, so careful selection of metals is critical for longevity and durability of operation in the long term.

- Many parts include rubber seals which provide additional protection against corrosive agents in the pumped environment while also providing a secure fit between individual pieces – helping eliminate any leakage from occurring during operation.

Composition of Submersible Pump Spares

Submersible pump spares are made from high-quality materials such as aluminium, stainless steel, brass, copper, and cast iron. The materials used depend on the intended application of the submersible pump. For example, brass is used in acid-pumping applications exposed to harsh chemicals, while stainless steel is used in high-temperature and high-pressure applications.

Uses of Submersible Pump Spares

Submersible pump spares are used in various industries, including agriculture, mining, construction, and oil and gas drilling. They transport different liquids, including clean water, sewage, and chemical liquids, using different impellers, couplings, and shafts. For example, submersible pump spares are used in dewatering mines and construction sites, sewage and wastewater disposal, and underground oil and gas drilling.

Importance of Submersible Pump Spares

Submersible pump spares are crucial to pump efficiency, stability, and longevity. High-quality spares ensure pump effectiveness, reducing maintenance and repair costs. Submersible pump spares increase the capacity and pressure of the pump, improving water drainage and increasing productivity. Employing top-notch submersible pump spares guarantees the safety of workers and equipment, enhancing the reliability of the pump.

Uses of Submersible Pump Spares

Submersible pump spares can be used to maintain and repair submersible pumps. These spares are essential to keep the pumps in good working order and may include piston rings, bearing seals, impellers, diaphragms, O-rings, shaft sleeves etc. Regular maintenance with these spare parts helps ensure that submersible pumps last longer and are safe from wear and tear.

Conclusion:

Submersible pump spares are essential components of submersible pumps, enhancing their functionality, efficiency, and longevity. Understanding submersible pump spares’ properties, uses, and composition is crucial for efficient pump maintenance and replacement. These spares help to increase the pump’s capacity and pressure, improve water drainage, and ensure the safety of workers and equipment. Companies and industries employing top-notch submersible pump spares are guaranteed reliable and efficient pumping systems.