Water pumps are essential devices to move water from one location to another. They are employed in various industries, agricultural systems, homes, and water treatment processes. Understanding the different types of water pumps will help you select the right one based on your specific needs. In this blog, we’ll explore the most common types of water pumps and their applications.

Submersible Pumps

Image credit: Science Direct

What Are They?

Submersible pumps are designed to be submerged in water. The pump’s motor and casing are sealed inside a watertight compartment, allowing the pump to push water from beneath the surface to the desired location. They are ideal for use in wells, ponds, or flooded areas.

Common Applications

- Domestic use: Ideal for drawing water from deep wells for household use.

- Agriculture: Used for irrigation and agricultural water supply.

- Flood control: Frequently used in flood-prone areas for drainage.

Advantages

- Efficiency: More energy-efficient compared to other pump types.

- Silent operation: As they are submerged, they operate quietly.

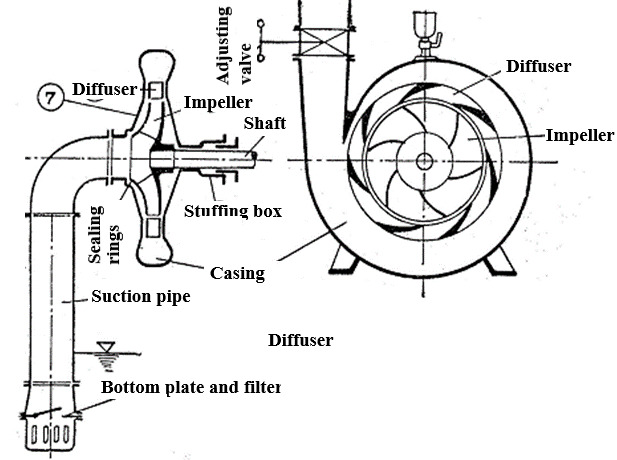

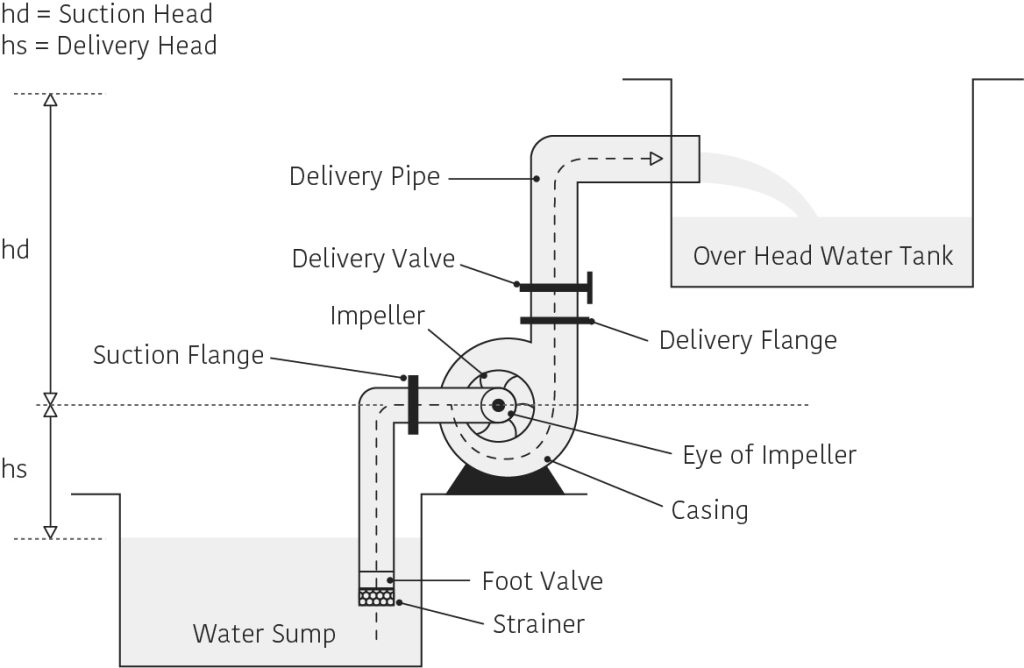

Centrifugal Pumps

Image credit: Research Gate

What Are They?

Centrifugal pumps are widely used for moving large volumes of water quickly. They use a rotating impeller to create centrifugal force, which pushes water out of the pump and into the discharge pipe.

Common Applications

- Water treatment plants: Commonly used in municipal and industrial water treatment systems.

- Industrial sectors: Applied in manufacturing, mining, and chemical industries.

- Agricultural irrigation: Ideal for irrigating large areas.

Advantages

- Versatility: Suitable for a wide range of applications.

- Low maintenance: Simple to maintain and repair.

Jet Pumps

Image credit: Science Direct

What Are They?

Jet pumps draw water from wells or reservoirs, typically above the ground. They create a vacuum by forcing water through a jet nozzle, which helps draw water from a lower level.

Common Applications

- Shallow wells: Best for shallow well applications (usually under 25 feet).

- Domestic use: Common in homes with no access to city water.

Advantages

- Affordability: Less expensive than submersible pumps.

- Easy installation: Since they are above ground, they are easier to install.

Monoblock Pumps

Image credit: Taro pumps

What Are They?

Monoblock pumps combine both the motor and pump into a single unit. These compact and efficient pumps are used where space is a concern.

Common Applications

- Residential use: For small household water systems.

- Agricultural use: Ideal for small-scale irrigation.

Advantages

- Compact design: Saves space, making them ideal for limited spaces.

- Cost-effective: Generally cheaper than more complex pump systems.

MultiStage Pumps

Image credit: Science Direct

What Are They?

Multistage pumps consist of multiple impellers arranged in series to increase pressure at each stage. These pumps are ideal for applications that require high-pressure water flow, such as lifting water from deep wells or transferring water over long distances.

Common Applications

- Water supply systems: Used in municipal water systems to boost pressure for distribution.

- Industrial applications: Used in industries that require high-pressure water for cooling, cleaning, or other processes.

- Agriculture: Used for irrigation in areas with high elevation or in long-distance water transfer.

Advantages

- High-pressure capability: This can generate higher pressure than single-stage pumps.

- Efficient for long-distance water transfer: Ideal for moving water over long distances or through tall systems.

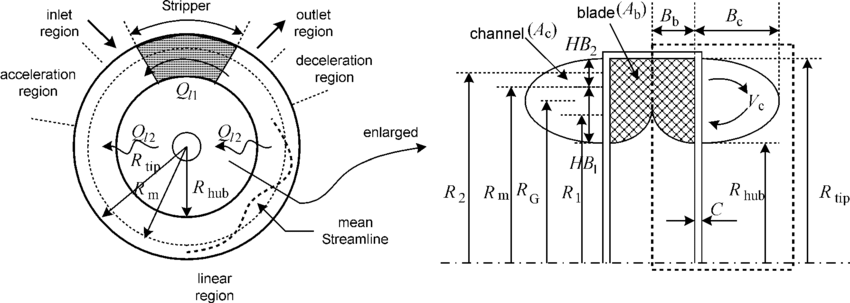

Regenerative Pumps

Image credit: Research Gate

What Are They?

Regenerative pumps use a single impeller to rapidly spin and create a high velocity, which generates pressure. These pumps are often used when a relatively low flow rate is needed, but high pressure is essential.

Common Applications

- Small-scale industrial use: Ideal for applications requiring moderate flow and high pressure, such as in pressure washers.

- Water treatment: Used for processes that require low flow rates but consistent pressure.

- Circulating systems: Often used in the circulation of liquids in heating systems.

Advantages

- High pressure at low flow rates: Suitable for applications where pressure is more important than flow.

- Compact design: Easy to fit in tight spaces.

Conclusion

Choosing the right type of water pump depends on your specific needs, including factors such as water flow rate, pressure, application, and efficiency. Whether you need a submersible pump for deep wells, a centrifugal pump for high flow, or a regenerative pump for high-pressure applications, there’s a pump suited for every task.