Submersible pumps are vital mechanical devices used in a variety of fields ranging from domestic water supply to large-scale industrial and municipal operations. Their efficiency, durability, and ability to operate underwater make them a go-to solution for many pumping needs. This blog offers an in-depth look at the various types of submersible pumps, their working principles, and their most common applications across industries.

What is Submersible Water Pump?

A submersible water pump is a hermetically sealed device designed to operate while submerged in the fluid it’s meant to pump. These pumps are usually submerged in wells, tanks, or water bodies, and their motor and electrical components are encased in waterproof housing to prevent damage from fluid exposure.

Because they work beneath the surface, submersible pumps do not require external priming. They offer a streamlined way to push water or other liquids upwards, often with greater efficiency than surface pumps. This design makes them ideal for deep-well water extraction, sewage handling, and even oil production.

How Does a Submersible Pump Work?

A Submersible Pump operates by drawing fluid into the pump body and then pushing it to the surface using centrifugal force. Here’s a closer look at the mechanism:

- Motor Activation: When electricity powers the motor, it begins rotating a shaft connected to one or more impellers inside the pump.

- Impeller Action: These impellers spin rapidly, increasing the velocity of the water or liquid.

- Pressure Generation: The kinetic energy is converted into pressure energy via diffusers, which allows the fluid to be pushed up through a discharge pipe.

Since the pump is immersed in the fluid, gravity assists in feeding liquid into the pump, making the process smooth and efficient without air pockets or cavitation.

What is Submersible Pump Used For?

Submersible pumps are incredibly versatile, serving a wide array of uses, such as:

- Agriculture: Farmers commonly use submersible pumps to extract water from deep borewells for irrigation. These pumps are also suitable for lifting water from canals or rivers to irrigate fields.

- Municipal Water Supply: These pumps are extensively used in municipal water distribution systems for extracting groundwater or pumping treated water to elevated storage tanks.

- Wastewater Management: In sewage treatment plants, submersible pumps are used to handle wastewater, sludge, and even raw sewage with high solid content.

- Industrial Applications: Industries use them for fluid handling in processing plants, especially when dealing with corrosive or viscous fluids.

- Construction Sites: At construction or mining sites, submersible dewatering pumps are used to remove accumulated water from pits or trenches to keep the site operational.

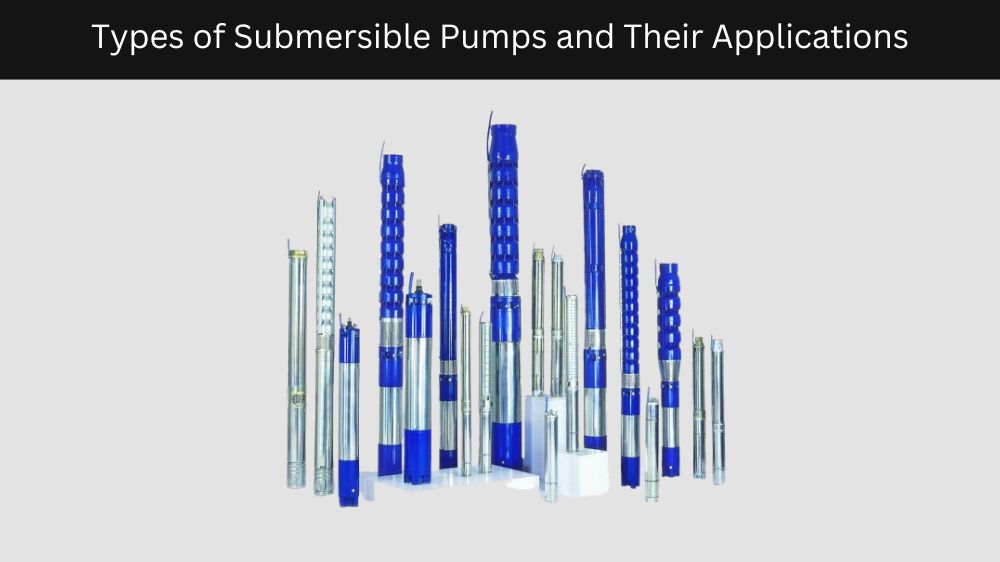

Types of Submersible Pumps

1. Borewell Submersible Pumps

These are long, cylindrical pumps designed to fit into narrow boreholes or wells. They are used mainly in rural and agricultural areas to extract underground water. With motors built to handle depths up to 1500 feet, borewell submersible pumps are ideal for areas with low water tables.

Applications: Agricultural irrigation, drinking water supply in remote areas.

2. Sewage Submersible Pumps

These pumps are designed to handle wastewater that contains solids, grease, or sludge. They often come with a grinder or cutter mechanism to break down solid materials before pumping.

Applications: Sewage treatment plants, building drainage systems, septic tanks.

3. Dewatering Submersible Pumps

Typically lightweight and portable, these pumps are used temporarily to remove water from construction sites, basements, or flooded areas. Though smaller in size, they are highly efficient and capable of handling sandy or dirty water.

Applications: Mining, construction dewatering, emergency flood relief.

4. Slurry Submersible Pumps

Built for the harshest environments, these pumps can handle abrasive and corrosive slurries commonly found in mining or chemical industries. Their internal parts are typically made of hardened materials to resist wear and tear.

Applications: Mining operations, dredging, heavy-duty industrial slurry transport.

5. Fountain and Aquarium Pumps

These are small, decorative submersible pumps used for circulating water in fountains or fish tanks. Although not industrial-grade, they are durable and provide a controlled water flow for aesthetic and biological balance.

Applications: Indoor fountains, koi ponds, aquariums.

Advantages of Submersible Pumps

- High Efficiency: Being submerged allows for direct fluid intake, reducing energy losses and improving pump performance.

- Low Noise Levels: Submersion of the motor helps dampen sound, resulting in quieter operation, especially in residential settings.

- Minimal Priming Required: Unlike surface pumps, submersible pumps don’t need to be primed since they are already within the fluid source.

- Versatility: Available in various models, submersible pumps can handle clean water, dirty water, sewage, and even slurry.

- Safety from Overheating: The surrounding liquid helps cool the motor, preventing it from overheating during extended operations.

Choosing the Right Submersible Pump

To select the best submersible pump for your needs, consider the following:

- Pump Capacity (Flow Rate): Determine how much water you need to move per hour or per minute.

- Head Height: Assess how high the water needs to be lifted. This is especially important in multi-storey buildings or deep borewells.

- Type of Liquid: The fluid’s characteristics (clean, dirty, viscous, or corrosive) determine the required material and pump design.

- Power Supply: Ensure compatibility with your power source, whether single-phase or three-phase.

Maintenance and Safety Tips

- Routine Inspections: Check for wear on impellers, seals, and cables to avoid sudden failures.

- Seal Testing: Ensure that the water-tight seals are intact to prevent fluid leakage into the motor.

- Motor Cooling: Never run a submersible pump dry, as it relies on the surrounding fluid for cooling.

- Proper Storage: If the pump is seasonal, clean and dry it before storing to avoid rust or buildup.

Conclusion

A Submersible Pump is a powerful, efficient, and safe solution for fluid transfer needs in a variety of settings. Whether you’re managing irrigation in fields, pumping wastewater in cities, or dewatering a flooded construction site, there’s a suitable submersible pump for every job. Understanding the different types and their specific applications can help you make an informed decision for your fluid-handling requirements.