Machined Components

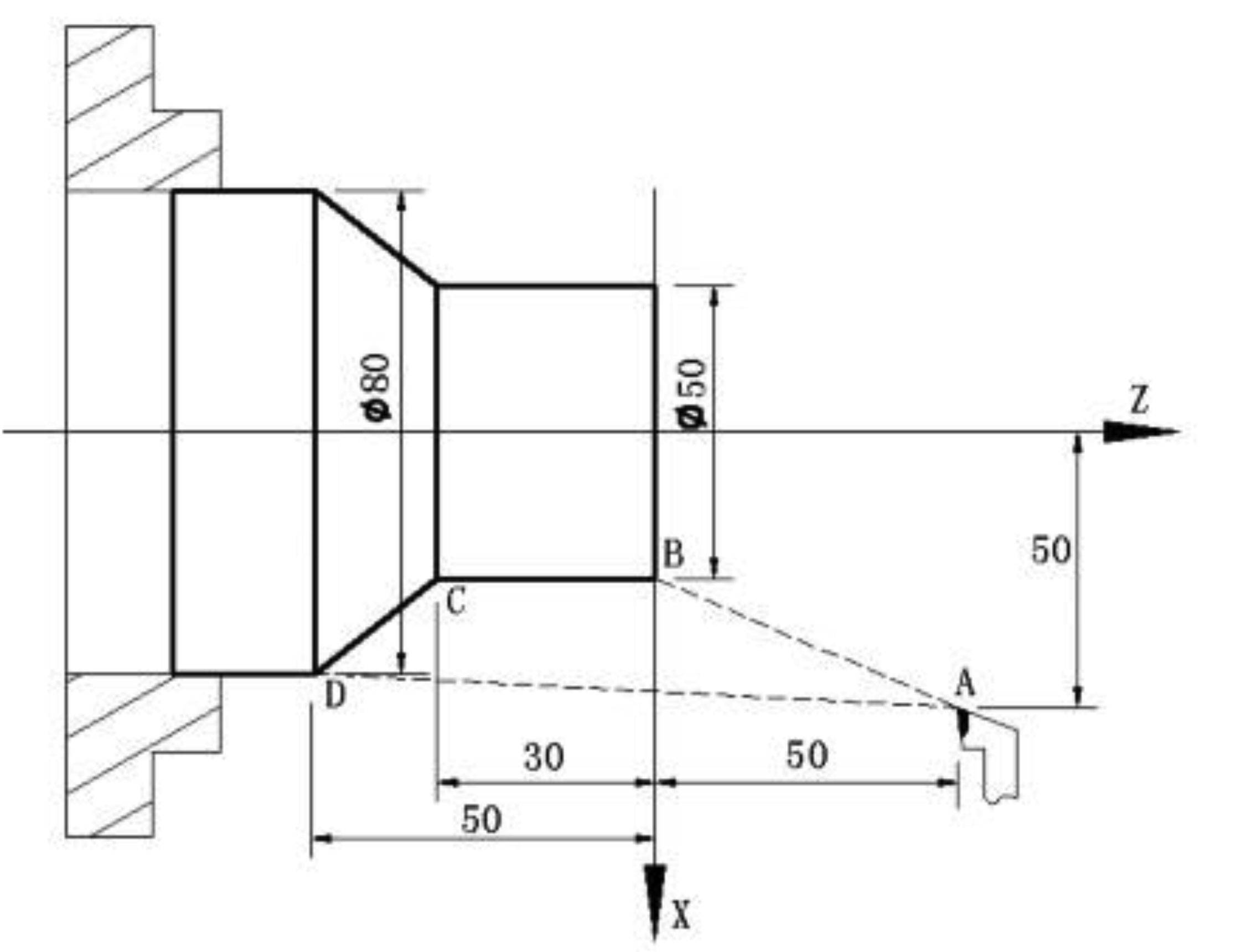

CNC Machined Components are precision-made components that offer superior structural integrity and a high level of accuracy. These components are used in a wide range of applications, from automotive engineering to medical device manufacturing. CNC machining offers many advantages over traditional fabrication processes such as higher production speeds, greater material utilization, improved surface finish and dimensional consistency, and enhanced product quality. The components can be produced from virtually any metal or plastic material and with a variety of finishes for customized performance.

Stainless Steel CNC Components, Stainless Steel CNC Machine Pins, SS CNC Machine Casting Component, SS CNC Lever Plate, Stainless Steel CNC Milling Components, SS CNC Components Manufacturer, SS Assembly Components Spare Parts Supplier in Mumbai, India.

CNC Machined Components provide excellent repeatability when machining complex geometries. Their high tolerance levels allow manufacturers to produce parts with tight tolerances faster than ever before. As the size and complexity of parts increases, so does the need for more precise CNC machining. With the latest technological advancements, the parts can be manufactured with even more accuracy and repeatability.

CNC Machined Components are widely used in many industries due to their superior performance and durability. In automotive engineering, they are used to create vehicle components such as engine blocks, gear boxes, suspension systems and powertrains. For medical device manufacturing, they are used to make implants and dental fixtures. They also have numerous applications in aerospace engineering where they can create highly specialized parts for satellites and rockets.

With CNC Machined Components, manufacturers can produce highly accurate and reliable parts with optimal properties for a variety of applications. Their features help reduce production costs while ensuring that the parts meet stringent industry standards.

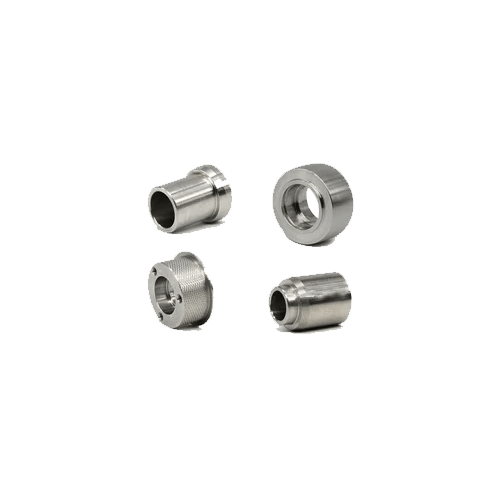

Stainless Steel CNC Turned Component, 304 Stainless Steel CNC Components, SS CNC Machined Components, Stainless Steel CNC Nobe, SS CNC Components, Stainless Steel Spherical Washer And Conical Set, Stainless Steel CNC Machine Forged Components in Mumbai.

Stainless Steel CNC Turning Components, Stainless Steel Ball End Fittings, SS CNC Precision Turned Component, 316 SS CNC Components, Stainless Steel Hardened Ground Bushes, SS CNC Ball Bearing Bush, Stainless Steel CNC Machining Component Stockist in India.

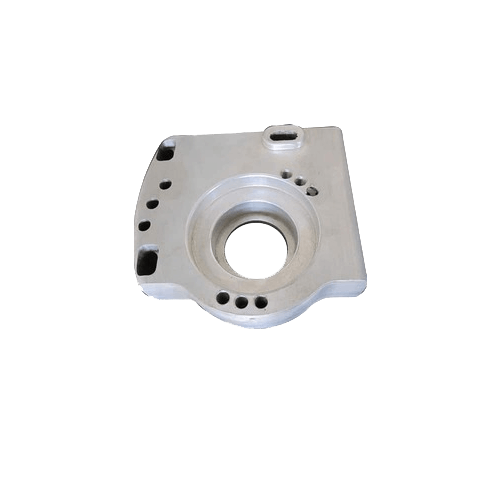

Specification of SS CNC Components

Size

All Sizes

Tolerance

+/- 0.005 mm, +-0.1-1 mm

Material

Stainless Steel

Grade

304, 316

Types Of CNC Machined Components

Stainless Steel Precision CNC Machined Components

MS CNC Machined Components

SS CNC Components

Exploded View SS CNC Machine Casting Component

Performance Curve SS CNC Precision Turned Component

Features Of Stainless Steel CNC Machining Component

Stainless steel construction – rust free – hygienic water supply.

Provides very good wear resistance due to stainless steel construction.

Pumps are equipped with replaceable stainless steel wear rings on the impeller.

Since pumps are made out of 100% stainless steel material they are best suited for hygienic drinking water application.

Wide range of pumps to match with different duty points.

Lighter in weight which reduces installation cost.

100% high-grade stainless steel inside and outside provides maximum reliability.

Better life in sand & other abrasives as well as sea water (salty) application.

Since Pumps are made out of stainless steel sheet metal, Resulting in low friction loss, high pump overall efficiency & low operating cost.

Incase of reduction in flow due to increase in clearance only the wear ring needs to be changed instead of impeller.

All pumps are equipped with a reliable non-return valve to reduce water hammer.

All cast iron parts shall be CED (cathode electrode deposition) coated for corrosion resistance with uniform coating and controlled deposition thickness of 20-30 microns.

The strainer is permanently fitted on the pump and it is not required to be removed when pump is coupled with motor, this ensures that strainer is always installed properly preventing damage to the pump from small stones entering the pump.

People Searches For SS CNC Turning Components

Stainless Steel Precision CNC Turned Components

Stainless Steel CNC Clamp

SS 304 CNC Components Price List

CNC Machined 316 Stainless Steel

Stainless Steel CNC Machining Industrial Parts Price List

SS CNC Turning Components Price List